In 2025, data has become the manufacturing sector’s most strategic asset—separating those who lead from those who lag.

AI investment has grown from around $2.2 billion in 2022 to nearly $9.5 billion in 2025. That kind of 5x jump shows how serious manufacturers are about using data to drive automation, performance, and profitability.

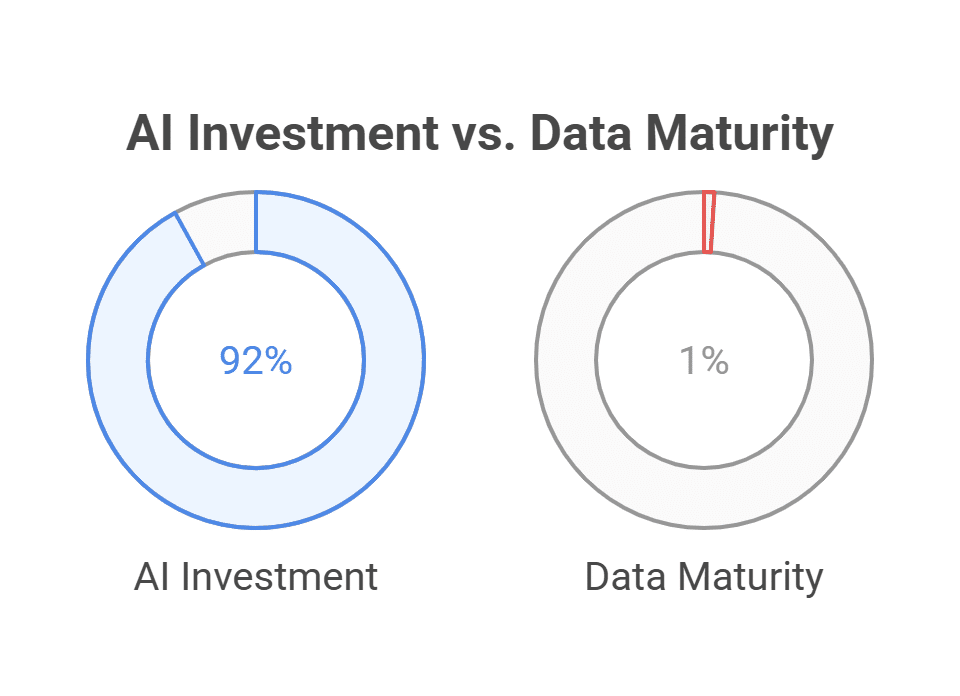

Over 92% of manufacturers say they’re planning to increase AI investments this year. But here’s the catch: only 1% have reached true data maturity.

Source: Deloitte 2025 Outlook, NAM Report

The real gap isn’t about who has data. It’s about who can trust it, use it in real-time, and link it to outcomes that matter—like OEE, scrap rate, or downtime.

1. Building Industrial-Grade Data Infrastructures

Modern manufacturers are designing scalable, interoperable architectures that unify shop-floor sensors, ERP systems, MES, and AI models.

Cloud alone isn’t enough – leaders are moving toward Unified Namespace (UNS) architectures to eliminate silos and ensure real-time data access plant-wide.

| Example: Siemens Siemens implemented a decentralized data mesh using UNS principles enabling over 70,000 users to access validated asset data in minutes instead of weeks. |

Their Azure-native platform processes over 1,000 data streams globally, improving responsiveness and standardization.

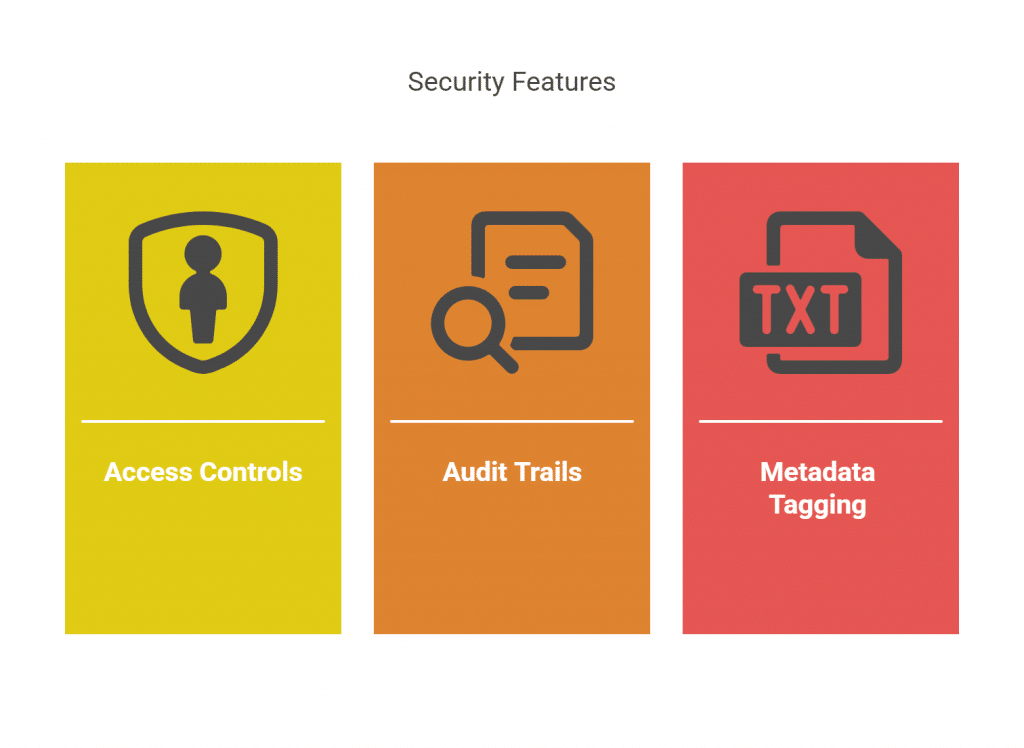

2. Treating Data Governance as a Strategic Enabler

Forward-thinking teams now see data governance not as a control function but as an operational accelerant. They implement:

Deloitte notes that 78% of AI-driven firms now have Chief Data Officers reporting directly to the CEO – a clear sign that governance is being tied to strategic execution.

3. Solving the Last-Mile Data Quality Problem

The biggest challenge isn’t capturing data—it’s trusting it when decisions are on the line. Top plants are now:

- Using edge AI to flag sensor anomalies (e.g., temperature spikes, pressure drift)

- Validating data in real-time before it hits the data lake

With more sophisticated tech, it’s becoming easier to surface the right information, at the right moment, with confidence.¹⁰ ¹¹

4. Aligning Data Strategy with Business KPIs

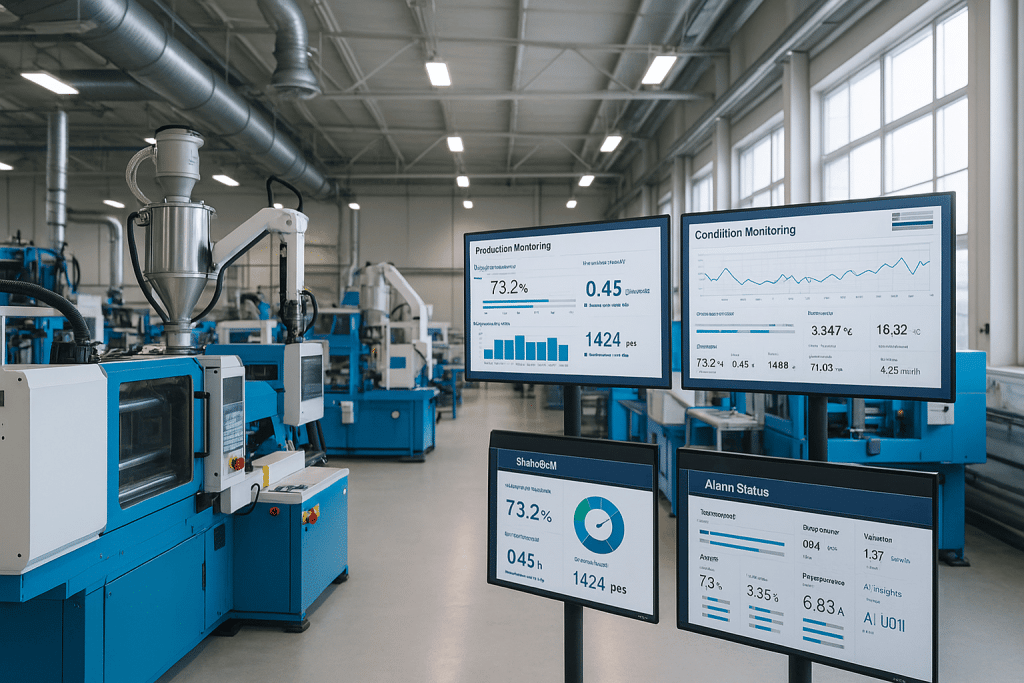

Having data is one thing. Making it speak the language of performance is what drives ROI. Leading manufacturers build role-specific dashboards for:

- Operators: OEE, MTTR, FPY, real-time downtime alerts

- Finance teams: Cost per unit, labor-to-output ratio

- Supply chain leads: Inventory turnover, lead time variability

This ensures that from floor managers to C-suite, everyone sees metrics that matter:

5. Preparing for AI’s Next Phase: Generative + Predictive Intelligence

As GenAI becomes operationally viable, data readiness becomes mandatory. Leaders are:

- Scoring data sets for structure, metadata context, and completeness

- Integrating RAG (retrieval-augmented generation) to ground AI in real operational data

| Example: Tier-1 Auto Supplier Used RAG-trained GenAI to reduce errors in technical manuals by 83% and enable instant frontline Q&A. |

The Road Ahead: Data Mastery as a Shared Advantage

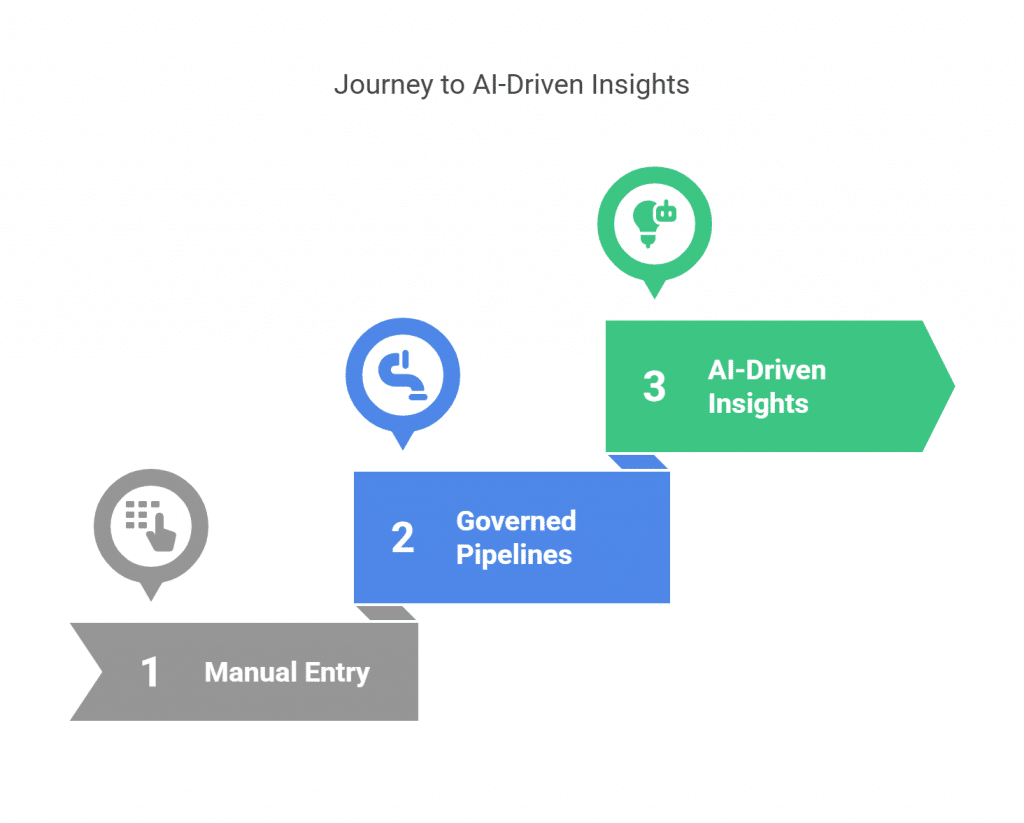

By 2026, manufacturers with mature data operations are projected to outperform peers by 34% in profitability. But the journey isn’t about doing everything at once—it’s about unblocking your next constraint.

Whether you’re working to reduce downtime, improve forecast accuracy, or enable operator-driven analytics, data maturity is about alignment, not overwhelm.

🔗 Looking Ahead:

Explore how Illumate supports next-gen BI in industrial environments.

Sources

- Deloitte 2025 Manufacturing Outlook

- NAM 2025 Trends Report

- QXimpact 2025 Trends in Manufacturing Data

- McKinsey Data Quality Research

- McKinsey Data-Driven Enterprise

- Deloitte + NAM combined analysis

- K2view GenAI Readiness Report

- CastorDoc Data Governance in Manufacturing

- McKinsey on AI Profitability Impact

- https://www.mckinsey.com/capabilities/quantumblack/our-insights/the-state-of-ai